XSORT CROSS BELT SORTER

The only Cross Belt Sorter (CBS) designed specifically for baggage handling.

XSORT Cross-Belt Sorter – Purpose-Built for Airport Baggage Handling

Overview

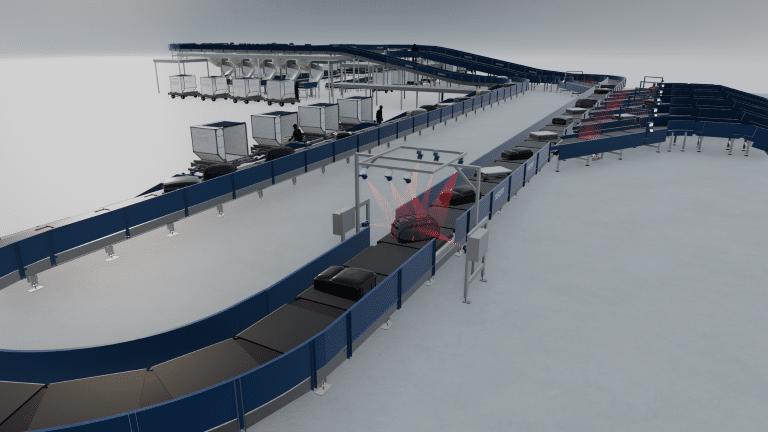

The XSORT Cross-Belt Sorter is the first high-speed sorting system specifically engineered for airport baggage handling, not adapted from parcel solutions. Purpose-built to handle diverse bag sizes at high throughput, XSORT delivers exceptional operational efficiency in a compact footprint - ideal for terminals with space constraints.

High-Speed, Low-Friction Baggage Transfer

XSORT enables smooth, low-friction transfers by matching the speed of the induction conveyor. Bags move seamlessly from the induction belt to the sorter and discharge with precision, reducing bag jams, misalignments, and system downtime. Its high-speed performance minimizes passenger wait times and increases system reliability.

Compact, Flexible, and Space-Saving Design

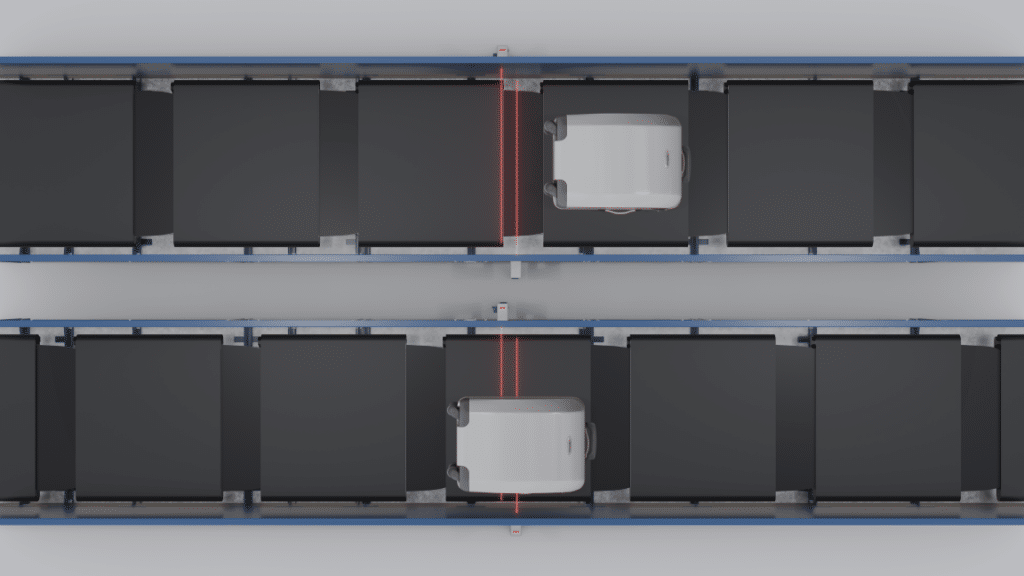

Designed for flexibility, XSORT features a low height, minimized footprint, and support for 5° and 11° incline configurations, allowing for versatile layout integration. The system dynamically adjusts to the size and position of each bag, ensuring precise induction and offload, and can recenter bags automatically if needed.

Built-In Efficiency and Smart Maintenance

XSORT uses a native IoT architecture and fewer moving parts, reducing wear and simplifying maintenance. With smart sensors and predictive analytics, maintenance needs are minimized. The system also intelligently adjusts its speed based on baggage volume - optimizing energy consumption while maintaining peak performance.

LOW CARBON FOOTPRINT | REDUCED ENERGY CONSUMPTION | RECYCLED ALUMINIUM | LIGHTWEIGHT CONSTRUCTION

Why Choose XSORT?

✅ Engineered for baggage - not parcels

✅ Compact design with low overhead clearance

✅ Handles variable bag sizes at high speed

✅ Incline-ready (5° and 11° options)

✅ Predictive maintenance and IoT diagnostics

✅ Energy-efficient, space-saving, and reliable

KEY SYSTEM COMPONENTS

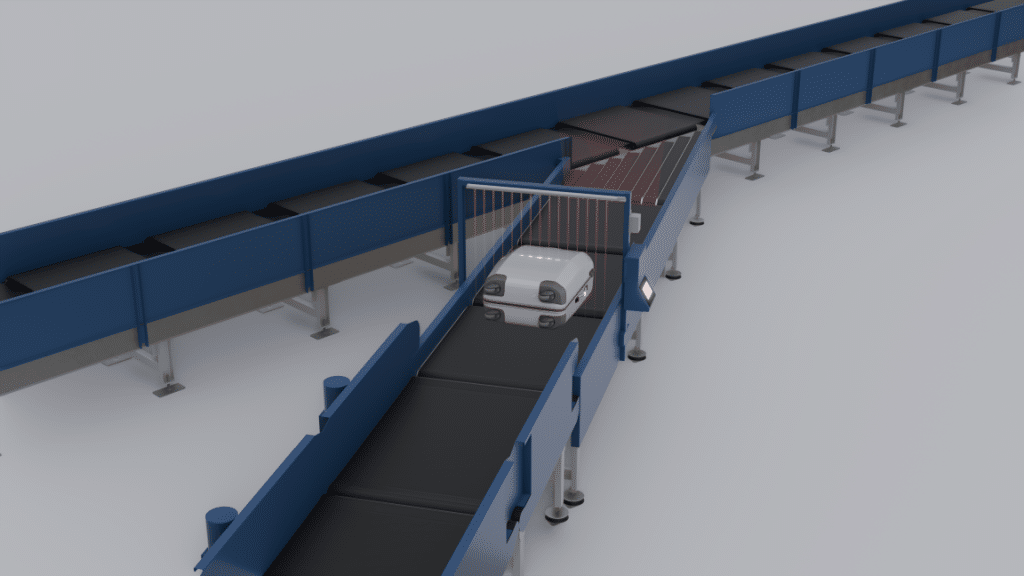

INDUCT LINES

- Metering conveyors to create space between bags

- Measuring light grids

- Multi-belt 30° merge conveyor

bag centering

- Detect location of bag in relation to the centre of conveyor

- Add/subtract offset and reposition bag to discharge position

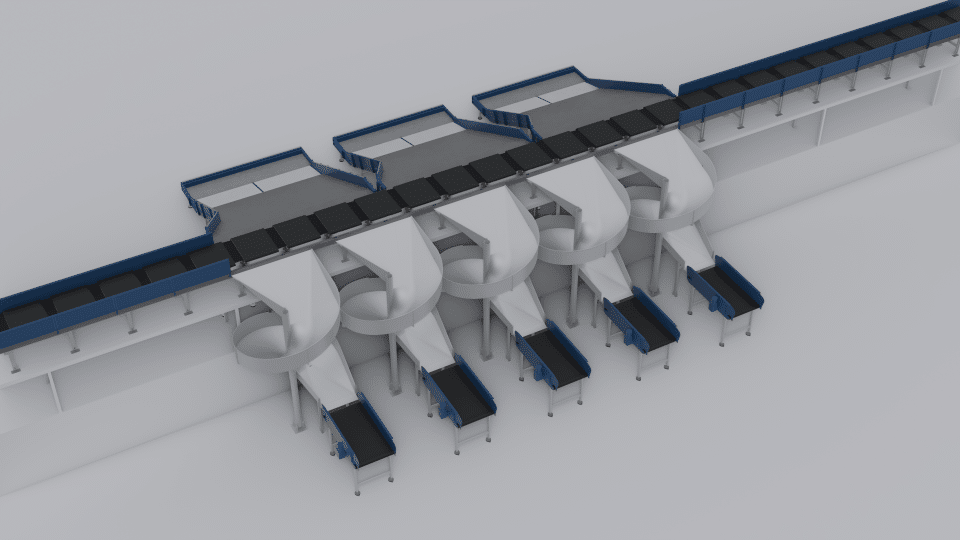

Chute Options

- Chute on conveyor

- Narrow chute for single offload

- Large chute for multiple offloads

- Spiral chute

REDUCED MAINTENANCE AND REAL-TIME SYSTEM MONITORING

Alstef Group provides comprehensive support for the XSORT system, including both on-site operations and maintenance services and remote support hotlines. At the heart of the system is BAGXPERT, Alstef’s native IoT-driven predictive maintenance platform. BAGXPERT helps reduce operational expenditure (OPEX) by identifying and resolving potential issues before they impact system performance. It predicts component wear, prevents sorter failures, minimizes downtime, and improves long-term system reliability and efficiency.

Real-time monitoring and control of the XSORT system is available through operator panels located at key points – including the induction area, main cabinet, and maintenance zone. These panels allow staff to adjust system speed, select carriers, and fine-tune conveyor operations for optimal performance.

In addition, Alstef Group’s Computerized Maintenance Management System (CMMS) supports efficient planning and execution of maintenance activities. It enables real-time tracking of work progress, schedules preventive maintenance tasks, and manages spare parts inventory – from purchase through to use. The CMMS also supports the allocation and management of human and material resources, ensuring smooth and well-coordinated system upkeep.

SIMPLIFIED PREVENTATIVE MAINTENANCE:

- Commonly available components with high uptime

- Contactless motorization of power supply with no moving parts - eliminates wear

- Sealed bearings - lubricated for life

SIMPLIFIED CORRECTIVE MAINTENANCE:

- Simplified disassembly

- The modular design of the electrical architecture of the carriers allows for easy dismantling – plug and play

- Simplified disassembly process for 30° induction belt

PERFORMANCE AND CONTROL

PERFORMANCE FEATURES

- Maintenance-free linear synchronous drive motors

- High-efficiency permanent magnet motors

- Wireless induction power system

- WiFi communication system

- Incorporates best-practice safety systems

- Redundancy of contactless electrical power system

- The electrical architecture based on harnesses cables for easy installation and maintenance

- Redundant safety PLC per safety standard EN619, prevents stoppage of the sorter in case of PLC failure

Compliant with the latest regulations including Machine Directive 2006/42/EC and EN619 requirements, XSORT is designed to optimise performance and efficiency through the use of lightweight trolleys and high-performance - low-friction wheels.

XSORT seamlessly integrates with existing airport SCADA system which provides a dynamic BHS visualization interface and also connects to existing Sortation Allocation Control (SAC) solutions. This facilitates real-time monitoring, precise sorting allocation, and efficient coordination with wider airport systems ensuring optimized baggage handling operations and enhancing overall system synergy.

ECO-CONCEPTION APPROACH: ENERGY SAVINGS

- XSORT’s speed adapts to capacity optimizing energy consumption

- XSORT utilises the latest generation of SLC synchronous linear motors with optimum efficiency

- Linear motors: reduced trolley weight and low wheel friction coefficients

- On-board conveyor motors provide low coefficient of friction between floor plates and belts