Our AGV & AMR range

A complete range of AGVs (Automated Guided Vehicles) and AMRs

French leader in AGV (Automated Guided Vehicle) intralogistics systems, Alstef Group offers a wide range of driverless trucks, pallet stackers and automated forklifts.

Our Automated Guided Vehicles optimize logistics performance by safely moving, transporting and storing heavy loads and pallets in factories and warehouses: inbound or outbound flows, storage or transfers between plant areas.

Our AGVs are meticulously designed and manufactured in France by Alstef Mobile Robotics (formerly BA Systèmes).

Automated Guided Vehicles: Main Features

- Localization systems: laser, optical, magnet …

- Navigation by targets, free navigation or mixed navigation

- Loads: from a box (400mm x 600mm) to an aircraft fuselage part

- Capacity: from a few kilograms to several tons

- Stacking height: up to 14 m

- Batteries: Lithium-Ion, lead, pure lead or gel

- Speed: up to 2.5 m / s

Tailor-made options

- Specific tools: clamps, pressers, double forks, telescopic forks, load stabilizers, long forks, sideshifters, fork positioners …

- Barcode identification or Datamatrix readers, RFID tags, etc.

- 3D camera systems

- Battery changing system: Autoswap® (automatic battery change), or Opportunity Charging

safety

Our AGVs & AMRs

GL - Automated Forklift

Learn more

GLR - Reach truck

Learn more

Tailor-made AGV

Learn more

GF - Autonomous Counterbalanced Stacker

Learn more

GT16 - Very Narrow Aisle AGV

Learn more

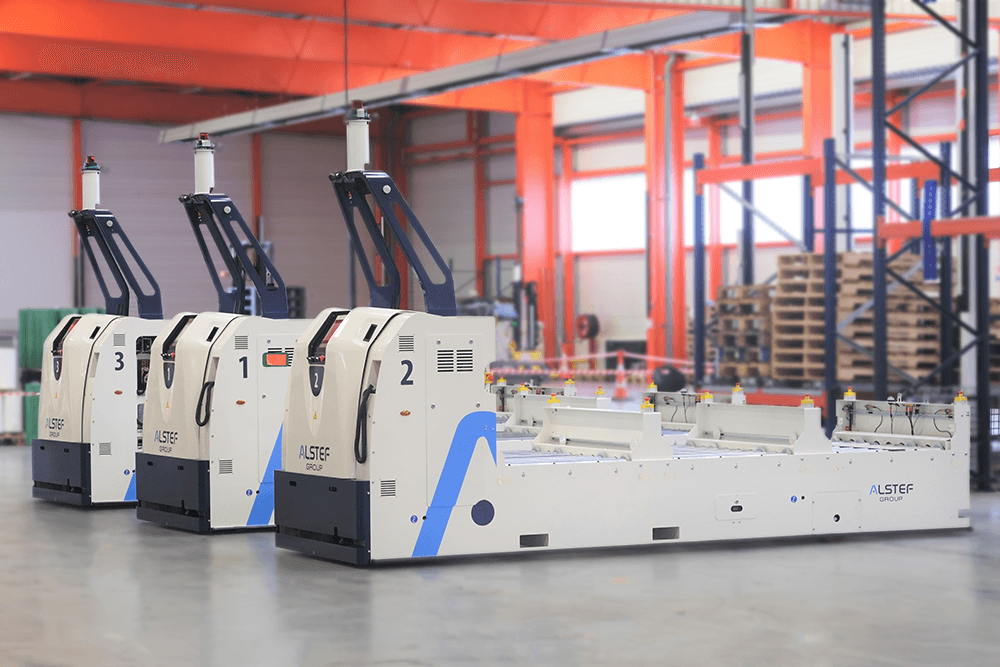

CM - Powered conveyors

Learn more

Loadstar - Autonomous Mobile Robot

Learn more

GL – Automated Guided forklifts

The compact and versatile AGV

- Suitable for narrow environments,

- Agile, these AGVs operate at the core of production lines,

- Particularly suitable for the infeed or outfeed of products.

Technical details

- Overall width: from 800 to 1000 mm

- Stacking height: from 1000 to 3000 mm

- Electric & hydraulic lifting

GF – Counterbalanced stacker

The versatile AGV

This automated counterbalanced vehicle is able to transfer a wide range of loads, including peripheral pallets and is compliant with any type of interface: shelving, conveyors, ground locations, etc.

The GF10 range

Beyond the intrinsic performance of counterbalanced trucks, the GF10.1 ensures optimum compactness allowing it to operate in constrained environments. It is equally well adapted to production lines, docks, and storage interfaces.

With 360 ° safety, GF10.1 guarantees the integrity of your loads, the safety of operators, while remaining efficient in terms of speed.

Technical details

- Overall width: 1000 mm

- Stacking height: up to 1500 mm

- Aisle width 3200 mm

- Electric lifting

- Li-Ion or lead-acid batteries

The GF12 range

Technical details

- The GF12 are compliant with all types of interfaces (shelving, ground locations, etc.)

- Stacking height: 8000 mm

- Available options: side shift carriage, tilt, positioner, spreader, loads stabilizer, clamps, mono / multi-fork carriage, etc.

The GF2 range

Supplied with 360 degree safety equipment, it moves safely within your work environment.

Technical details

- Overall width: 1650 mm

- Stacking height: up to 6500 mm

- Maximum transportable mass : 2 x 1400kg

CM – Powered conveyor

The key element for high flow rates

Technical details

- From 1 to 4 loads – up to 1500 kg per load

- Long-side or short-side loading (rollers, chains, modular belt conveyors)

- Transfer height: 500 mm as standard

- 2 possible levels of transfer (upper level: finished product pallets / lower level: empty pallets)

- Kinematics adapted to the environment (single or twin turrets)

- Available options: variable dimensions of loads, anti-tipping device, stabilizers, etc.

GT16 – VNA truck

Very narrow aisle (VNA) storage solution

The GT16 meets the specific requirements related to the automation of very narrow aisle and high-bay storage. Loads are picked up and dropped off laterally.

Advantages

- Very narrow aisle storage (VNA),

- Speed,

- Flexibility,

- Single pallet access,

- Handles the flows of all products: packaging items, raw materials, finished products, etc.

- Is suitable for severe environments: including freezing temperature environments.

Technical details

- Stacking height: up to 12 m as standard

- Maximum loads of 1200kg

- Tri-lateral head

- Adaptability to the dimensions of your loads

- Mixed laser navigation: free + targets

- Speed up to 2.5 m / s

- Available options: sideshift carriage, positioner, etc.

GLR – Automated Reach Truck

The AGV operating in narrow aisles

Advantages

- Compactness,

- Safety,

- Stability,

- Productivity,

- Optimization of storage capacities.

Technical details

- Stacking height: up to 9 m as standard

- Payload up to 1400 kg

- Speed up to 2.5 m / s

- Available Options: side-shift carriage, tilt, positioner…

LOADSTAR

Mobile Robot for the Transport of single pallets

Compact and robust, Loadstar can handle pallets up to 1400 kg and allow to save up to 20% of floor space. This “turtle” AGV-AMR replaces traditional conveyor systems and brings flexibility and reactivity to the heart of systems with strong flow variations.

Advantages

- Boosts horizontal transfers instead of traditional conveyors,

- Modular, it is suitable for all existing environments,

- Optimizes order preparation.

Technical details

Custom-made Automated Guided Vehicle

Your tailor-made agv-amr

Some applications demand a uniquely customized solution. We take pride in integrating specific tools and devices, crafting an AGV that fits your unique needs like a glove.

- Versatile Load handling: From dimensions to shape to stability, our AGVs are designed to handle it all. Pallets, steel frames, paper reels, waste bins, tanks, and vats – we’ve got you covered!

- Load Handling Equipments: Choose from a variety of load handling equipment options, including sideshift carriage, fork positioner, clamps, tilting forks, pressing, and stamping tools. Versatility at its finest!

We can support you in your project.

Contact us

Alstef Group supports your AGV project

contact@alstefgroup.naphix.com

+33 (0)2 99 85 11 00